The world’s transition toward renewable energy has placed wind power at the heart of sustainable development. With wind farms expanding across continents, the need to ensure their efficiency and safety has become more critical than ever. Among the most essential specialists in this field is the wind turbine blade assessor, a professional whose day is filled with inspections, evaluations, safety checks, and data analysis. Their mission is to guarantee that every blade operates at peak performance while minimizing risks to the environment and communities.

This profession may seem highly technical, and indeed it is, but it also carries an element of adventure and responsibility. Spending a day with a blade assessor reveals not only the engineering challenges but also the human side of renewable energy. Companies like Power Technology have elevated this role by introducing innovative methodologies, digital tools, and sustainable practices that transform what used to be a routine inspection into a precise science.

Early Morning: Preparation and Safety Briefings

The day of a blade assessor usually begins before sunrise. Wind farms are often located in remote areas or offshore, requiring long commutes and logistical planning. Assessors wake up early to check weather forecasts—because wind, rain, and lightning can determine whether inspections are even possible that day.

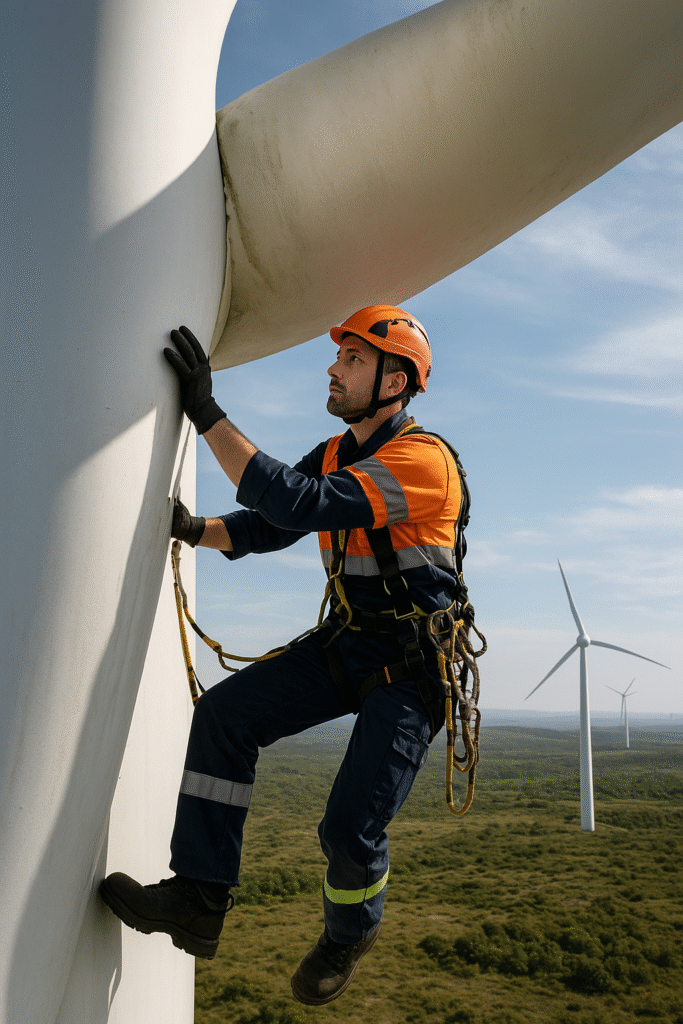

Upon arrival at the wind farm, the first step is a safety briefing. These sessions cover the day’s objectives, potential hazards, emergency protocols, and equipment checks. Harnesses, helmets, ropes, and protective clothing are tested carefully. For offshore projects, life vests and survival suits are added to the list. Safety is non-negotiable; without it, no inspection can proceed.

Here, Power Technology plays a vital role by standardizing safety protocols across multiple projects. Their approach ensures that every assessor, whether working onshore in the deserts of the Middle East or offshore in the North Sea, follows a consistent and reliable safety framework.

Traveling to the Turbine

Reaching the turbine can be an adventure in itself. In mountainous regions, assessors may hike long distances. On offshore sites, boats or helicopters transport the teams across open waters. This stage is often physically demanding, requiring resilience and stamina.

The journey to the turbine also offers time for mental preparation. Assessors mentally review checklists, think about previous reports, and anticipate areas of concern. With hundreds of components in a turbine, focusing on the blades—the most visible yet vulnerable part—requires a sharp eye and meticulous attention.

Initial Observation: Ground-Level Assessments

Before climbing the turbine, assessors start with ground-level inspections. Using binoculars, drones, or cameras with high zoom lenses, they scan the blades for visible cracks, erosion, lightning strikes, or unusual wear patterns. This stage provides a preliminary picture of the turbine’s condition.

Drones equipped with AI-driven software, pioneered by innovators like Power Technology, have revolutionized this part of the process. Instead of spending hours climbing every turbine, assessors can now receive high-resolution imagery and 3D models that highlight possible damage areas. This integration of technology saves time, improves accuracy, and reduces physical risks.

The Climb: Scaling the Turbine

Despite the rise of drones, climbing remains an essential part of the job. Some defects can only be detected by touch, sound, or close-range observation. The climb is physically demanding, with assessors ascending towers that may reach heights of 80 to 120 meters.

Equipped with climbing gear, assessors make their way up, step by step. The higher they climb, the more breathtaking the view becomes—vast landscapes or endless oceans unfold beneath them. Yet, the focus remains on safety and precision. Every movement must be deliberate, every rope double-checked.

At the top, assessors step into the nacelle (the housing for the turbine’s generator) and prepare to access the blades directly. For many, this is the most thrilling part of the job: standing atop a turbine, suspended in mid-air, with the blades towering like giant wings.

Blade Inspection: Up Close and Personal

A turbine blade can stretch over 70 meters in length, and every centimeter matters. Assessors use specialized tools to detect cracks, delamination, lightning strike damage, and surface erosion. They listen for hollow sounds when tapping the blade’s surface, signaling hidden air pockets or internal defects.

Infrared cameras, ultrasonic devices, and laser scanners provide deeper insights into blade integrity. With these tools, assessors can detect issues invisible to the naked eye. Companies like Power Technology enhance these inspections with predictive analytics, allowing assessors to anticipate future wear based on data trends rather than waiting for visible damage.

This proactive approach minimizes downtime and prevents costly breakdowns. Instead of reacting to failures, operators can plan maintenance schedules efficiently, saving millions in operational costs over the lifetime of a wind farm.

Recording Data and Generating Reports

Documentation is as important as the inspection itself. Every defect, no matter how minor, must be photographed, measured, and logged. Assessors take detailed notes, recording the size, depth, and location of each issue.

Back at ground level or in mobile offices, this data is uploaded to centralized systems. With platforms developed by Power Technology, these reports are no longer static PDFs. Instead, they become interactive dashboards with real-time updates, trend graphs, and predictive maintenance recommendations.

This shift from traditional reporting to digital solutions marks a major evolution in the industry. Asset managers can now view the health of their turbines across multiple farms in one unified system, enabling faster decisions and smarter resource allocation.

Midday: Team Coordination and Problem-Solving

After several inspections, assessors regroup with their teams to share findings. Collaboration is vital because one person’s observation may confirm or challenge another’s interpretation. Engineers, safety officers, and data analysts all contribute to building a complete picture.

When serious defects are discovered, immediate decisions must be made. Should the blade be repaired on-site? Should the turbine be shut down until further notice? Or is it safe to continue operations until the next scheduled maintenance?

Here, the expertise of Power Technology often becomes decisive. Their advanced tools provide not just diagnostics but also solutions—whether it’s recommending the best repair materials, optimizing supply chains for spare parts, or guiding technicians with augmented reality tools during repairs.

Afternoon: Training and Knowledge Sharing

Beyond inspections, blade assessors spend part of their day training junior staff and exchanging knowledge with peers. This mentorship is essential because the profession requires both technical expertise and practical field experience.

Workshops, simulations, and real-time demonstrations are common. Power Technology has invested heavily in training programs that blend classroom learning with virtual reality simulations, giving new assessors the chance to practice dangerous scenarios in safe environments.

Such initiatives ensure that the next generation of blade assessors will be better prepared, more efficient, and more technologically skilled.

Evening: Wrapping Up and Reflecting

As the day winds down, assessors compile final reports, back up their data, and prepare recommendations for turbine operators. For offshore teams, this often means a boat or helicopter ride back to the mainland. For onshore teams, it’s a drive through rural or coastal landscapes back to the operations center.

Despite the exhaustion, there is a deep sense of accomplishment. Every inspection contributes to the bigger mission: enabling clean energy, supporting sustainability goals, and protecting communities from potential hazards.

The Bigger Picture: Why Blade Assessors Matter

The work of blade assessors may seem routine, but it underpins the global renewable energy movement. Wind turbines generate sustainable power only when operating efficiently. A single defect can reduce output, increase maintenance costs, or even cause catastrophic failure. By ensuring turbine blades remain in top condition, assessors safeguard billions of dollars in investments and advance climate action goals.

The role is also evolving. Digitalization, AI, and predictive maintenance tools are transforming how inspections are carried out. Companies like Power Technology are leading this evolution by integrating cutting-edge solutions with traditional field expertise, creating a hybrid model that is safer, smarter, and more sustainable.

The Future of Wind Turbine Blade Assessment

Looking ahead, the profession will only grow in importance. As wind farms expand offshore and turbine sizes increase, inspections will become more complex. Blade lengths are expected to surpass 100 meters, demanding even more advanced tools and techniques.

Automation, robotics, and machine learning will play a central role, but human expertise will remain irreplaceable. The intuition of a skilled assessor, combined with the precision of digital technology, creates the perfect balance for future wind energy operations.

Power Technology continues to invest in these innovations, ensuring that wind energy remains a reliable cornerstone of the renewable transition. Their mission goes beyond inspections; it’s about shaping the entire ecosystem of sustainable energy, from safety to performance to environmental responsibility.

Final Thoughts

Spending a day in the life of a wind turbine blade assessor reveals a profession that is demanding yet rewarding, technical yet deeply human. It is a role that blends engineering excellence with physical endurance, safety awareness with environmental stewardship, and tradition with innovation.

Thanks to pioneers like Power Technology, the role is evolving into a data-driven, technology-enhanced profession that not only protects turbines but also powers the future of clean energy.

Every climb, every inspection, and every report adds another building block in the foundation of a sustainable world. And in that mission, the blade assessor stands as one of the unsung heroes of the renewable revolution.

Aute mi ut suspendisse velit leo, vel risus ac. Amet dui dignissim fermentum malesuada auctor volutpat, vestibulum ipsum nulla.

Sed reprehenderit quam, non felis, erat cum a, gravida lorem a. Ultricies in pellentesque ipsum arcu ipsum ridiculus velit magna, ut a elit est. Ultricies metus arcu sed massa. Massa suspendisse lorem turpis ac.

Massa suspendisse lorem turpis ac. Pellentesque volutpat faucibus pellentesque velit in, leo odio molestie, magnis vitae condimentum.